Carbon Nanofoam Paper

Carbon Nanofoam Paper

The primary applications for Carbon Nanofoam Paper are for energy storage such as in ultra-capacitors and ion-separations for water purification and desalination.

What are nanofoams?

Electrically conductive carbon nanofoams have many of the properties of traditional aerogel material. This unique class of porous materials is available in the form of monoliths, granules, powders and papers. They are synthetic, lightweight foams in which the solid matrix and pore spaces have nanometer-scale dimensions. Prepared by sol-gel methods, nanofoams typically have low density, continuous porosity, high surface area, and fine cell/pore sizes. The foams are also electrically conductive and have a high capacitance.

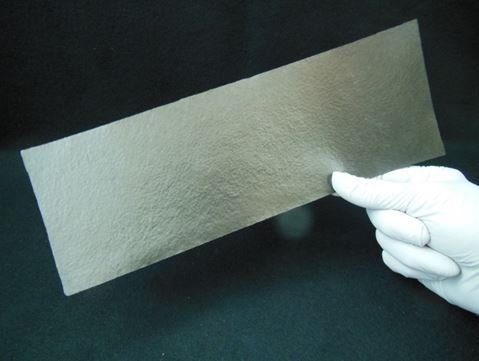

Standard densities of carbon nanofoams range from 0.25 to 1.00 g/cm3. Carbon nanofoams precursors can be infiltrated into a carbon fiber mat that, when carbonized, will result in paper-like electrode material 0.007 to 0.050" thick.

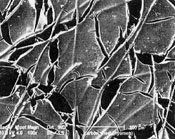

Morphology examination by scanning electron microscope shows an open cell structure and continuous porosity. The particle size and pore spacing is a function of density and the polymerization chemistry used during the sol-gel process.

Properties of Nanocellular Carbon Foam

Low density carbon nanofoams (~0.25 g/cm3) have the largest cell/pore size with particle diameters of up to 100 nm and pores at least 500 nm. High density carbon foams (abt. 0.8 g/cm3) have ultra fine particles and pores of less than 1000.

Standard Sheet Size: 3.5 x 10"

Standard Thickness: 0.010"

Thicknesses of 0.005 to 0.050" available.

Grade I and II electrodes have been tested in capacitive deionization cells and the electrodes are found to be completely suitable for a range of capacitive deionization (CDI) applications.

Carbon Nanofoams Electrodes

Nanofoam carbon paper is an alternative to woven carbon cloth for electrodes and are superior to woven carbon fiber electrodes in many applications because of their high surface area, low resistance and high relative capacitance. The electrode material is flexible and can be pre-formed into almost any desired shape. They posses about 20% bulk porosity resulting in good flow characteristics, and have both nano and meso porosity. There is virtually no contact resistance within the carbon electrode.

SEM photographs of this composite sheet shows platelets of carbon nanofoam firmly attached to random carbon fibers, interspersed with macro porosity. The macro porosity of the standard sheet is about 20% and the ratio nanofoam to carbon fiber is about 80% by weight.

Quick Links:

Machinable ceramic China Corp.

Tel: +86-755-84866656

Building 4, Lihao Industrial Park, No. 78, Ainan Road, Longdong, Longgang, Shenzhen, China.

Request a Quote

© 2023

All Rights Reserved |Machinable ceramic China Corp.

inquiry.machinable@ceramics-parts.com

Proudly built using the China