Oil Field Parts

Oil Field Parts

Specific property of complete SIC plunger and plunger sleeve:

It can be applied widely to be oil field pump plunger within oilfield applications and improve the service life of plunger greatly, so it is a kind of high quality plunger material, for it has outstanding performance such as wear ability, anti-corrosion, and high temperature-resistant.

The scope of production capacity for SIC plunger:

- Length: <800mm

- Outside diameter: <300mm

- The thickness of pipe wall: 5 - 10mm

- Surface roughness: above Ra0.8

We can also make them in zirconia material.

The Special Ceramic Liner for Mud Pump

It is made of Silicon Carbide or Intensify Toughness Alumina material which is authorized by some Chinese and American companies. Based on the advantages such as HRA90, super grinding resistance and less coefficient of linear expansion etc. The working life will be around 3000 - 5000 hours and is several more times than Dual Metal Liner under normal working condition.

Special Ceramic Pump Valve

The Special Ceramic Pump Valve, with high temperature-resistance and anticorrosion, can replace common pump valve. Also with drippy structure and guiding device, the Special Ceramic Pump Valve can be shut down quickly with excellent sealing security and guiding fit exactly; the flow gate is 1.4 times as common pump valve, it increases complete pump barrel filling and working life a lot.

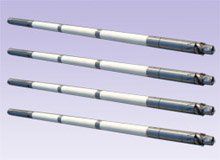

High temperature-resistant & anticorrosive Ceramic Sucker Rod Pump for Steam Drive Well

The Ceramic Sucker Rod Pump, assembled together with special heat-resistant & anti-corrosive alloy steel pump cartridge and anti-corrosive& high temperature-resistant ceramic plunger, can resist high temperature working condition of more than 300°C and also possesses the advantages such as anti-corrosion, non-forming encrustation and long working life.

High temperature-resistant & anticorrosive Ceramic Plunger for Steam Drive Well

Due to the function of composite shock absorption device, the Ceramic Plunger can bring the buffing powder of 30000Pa. Some other technical indexes are:

- Resisting high temperature of 350°C, HRA90Bending Strength 1.5MPa

- Coefficient of heat expansion 6.5 X 10-6/°C

- Surface Roughness Ra0.5

It is not corroded by acid under the well, therefore, the working life of the Ceramic Plunger is several times more than common metal plunger.

Quick Links:

Machinable ceramic China Corp.

Tel: +86-755-84866656

Building 4, Lihao Industrial Park, No. 78, Ainan Road, Longdong, Longgang, Shenzhen, China.

Request a Quote

© 2023

All Rights Reserved |Machinable ceramic China Corp.

inquiry.machinable@ceramics-parts.com

Proudly built using the China